Every day, new companies that rely on automated systems to maintain the level of competitiveness in the market. Often used in the automotive industry, the industrial robots became such a powerful asset to work in other sectors, and the demand for these smart machines is growing each and every day in Brazil.

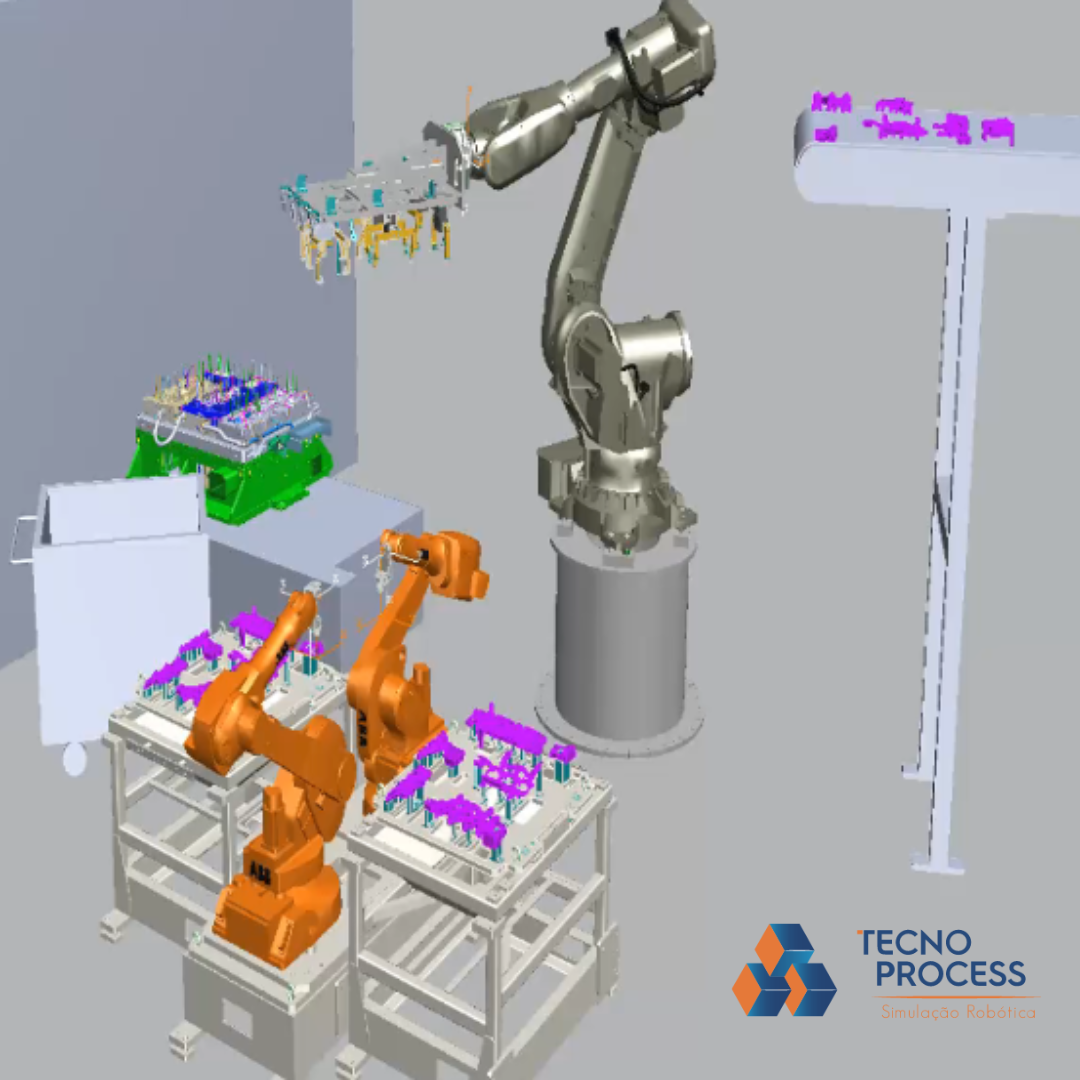

Regardless of whether it is a factory, large or small, there is a robotic solutions that are able to meet their needs, and optimize your results.

Check it out right now what are the benefits of automation to the industry!

1 — it Increases the productivity of

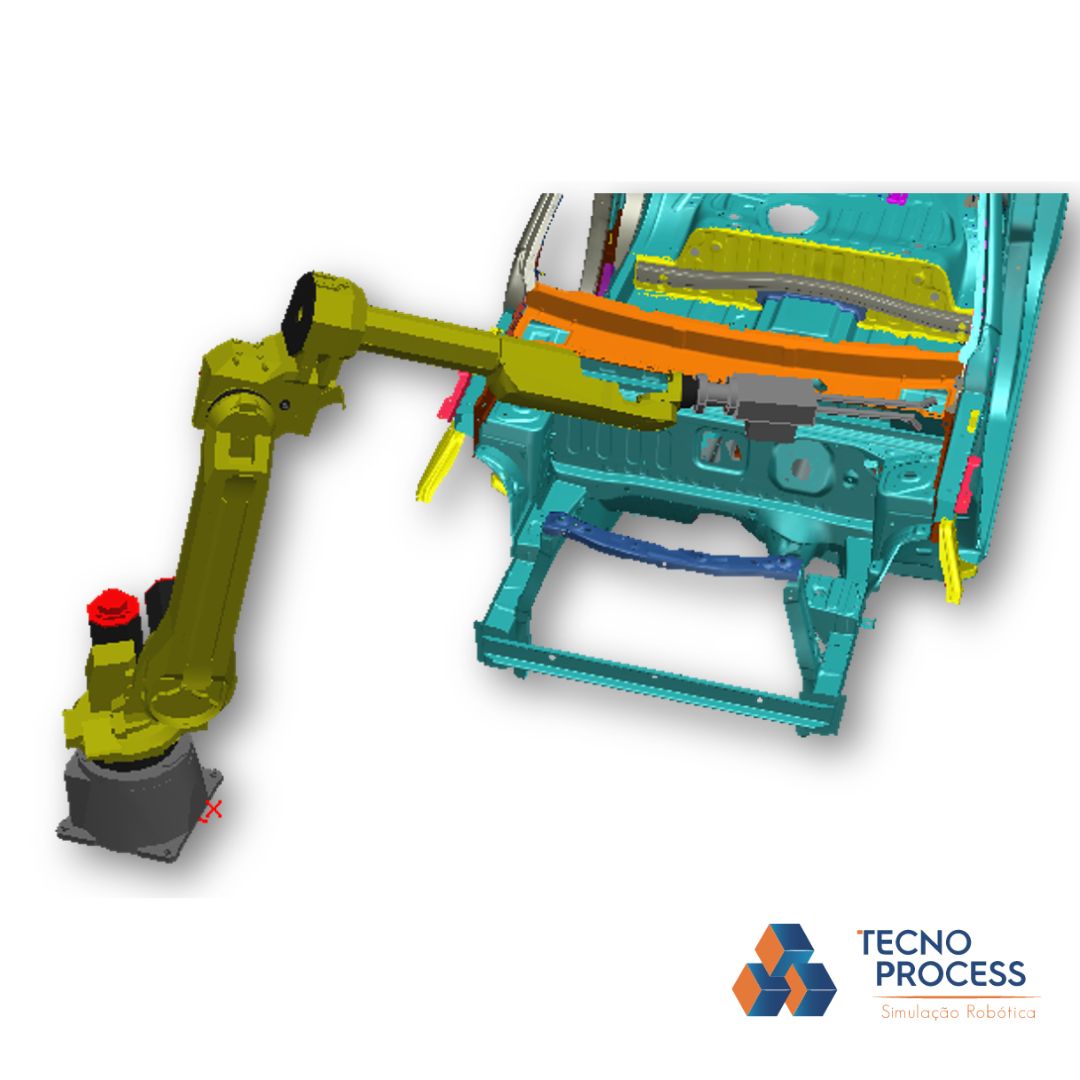

With the implementation of robotic automation, it is possible to increase the productivity of your plant. As human beings, they need breaks and the rest of the robots can work 24 hours around the clock, every day of the year, and often without the supervision of a human operator.

Depending on the programming or configuration of the robot in the industry, you can perform stunts and repetitive movements with the precision and agility, while reducing errors and may be in the process of manufacturing and assembly of its products. In this way, there is an optimization in the production, thus increasing substantially the total production capacity of the plant.

When you make use of the solutions by way of Tecnoprocess guarantees the highest productivity and efficiency in your production line.

On the Tecnoprocess: https://tecnoprocess.com/sobre-nos/

2 — the Quality of the products and satisfaction of our customers

Perhaps one of the biggest advantages of investing in robots, industrial automation, is that there are no errors during the manufacturing and assembly of its products.

To the contrary, the employees, the human and the robot in the manufacture of products that are designed and configured to perform a number of specific actions repetitively, and organized in this manner, there is no room for error, since every movement is precise and calculated. As a result, there is a consistency in the manufacturing process, which ensures quality and superior.

To reduce the chances of mistakes in the making, it is also possible to experience a reduction in the cost of re-work, and damage to the product. All of this leads to an increase in the perceived value of the product, as well as a high level of satisfaction among clients and customers.

3 — the cost effectiveness and safety in the workplace

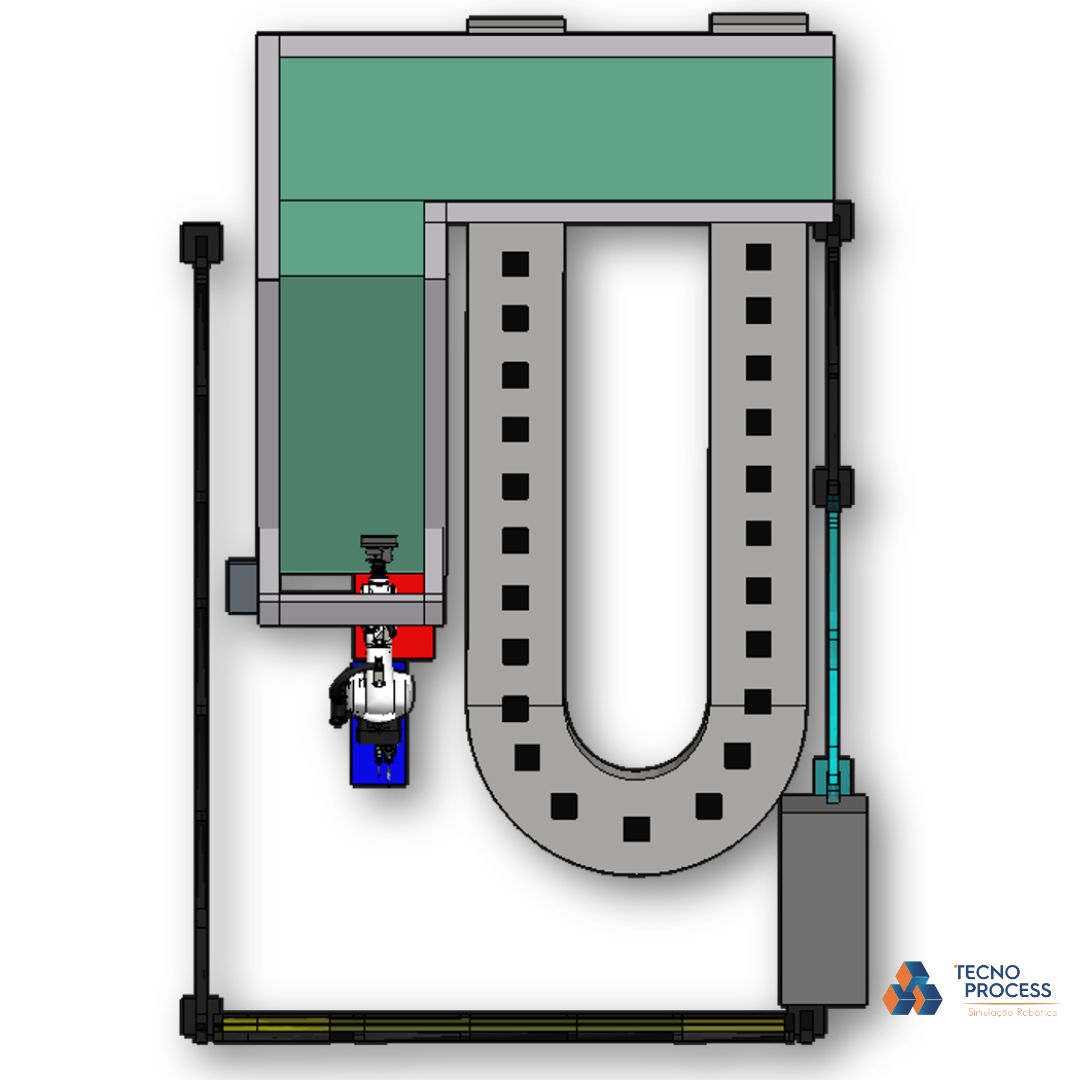

The use of robots to automate the processes of manufacture and assembly to help reduce the operating costs in a general way, because in addition to being able to significantly increase its production capacity in a short period of time, it can also partially compensate for the labor of man.

Robots, industrial Tecnoprocess they feature excellent performance, and also feature low power consumption of electrical energy, thus helping in the reduction of costs. Initially, it may seem like a high investment, but the truth is that the robots will reduce the cost of production and the value of the investment can be recovered in a short time, precisely because of the increase in productivity, that is, the robots can provide.

Conclusion

It is worth noting, also, that the robots can mitigate the impact of accidents in the workplace, in that they are able to perform tasks in hazardous or harmful to human beings, such as contact with chemicals, gases, high temperatures, and knives, among other things. This is an effective way to provide greater safety in the workplace, and to ensure that their employees remain healthy and safe.

Gain access to: industry 4.0

All of these benefits in the areas of industrial automation show you the importance of investing in and implementing industrial robotics, once for all, in the production line.

Get the high-quality and effective solutions in robotics Tecnoprocess to get into the industry 4.0!

Please click on the link below to talk to our experts!