Every business owner wants to exponentially increase their profits, to gain more recognition in their field of expertise, or even to make their products and services and is a reference in the market.

What happens is that, it is not always achieve such a feat it is simple, it is necessary to “get out of my comfort zone” in order to gain more and more pleased with the staff to be efficient, and, of course, dramatically decreasing the number of errors committed on a daily basis by the staff.

Stay right here to find out about the behaviors that may be hindering the productivity of your company or the industry, and here's how to fix them!

The lack of change in

The first and most important reason for a delay in the effort to transform, profit and the structure of the enterprise is the lack of commitment to the change. However, the fear of the “new” that is present in all human beings, and this fact is associated with the experiences of the past “failure” of the change of management, or of the structural members of the company to make any of the changes a challenge.

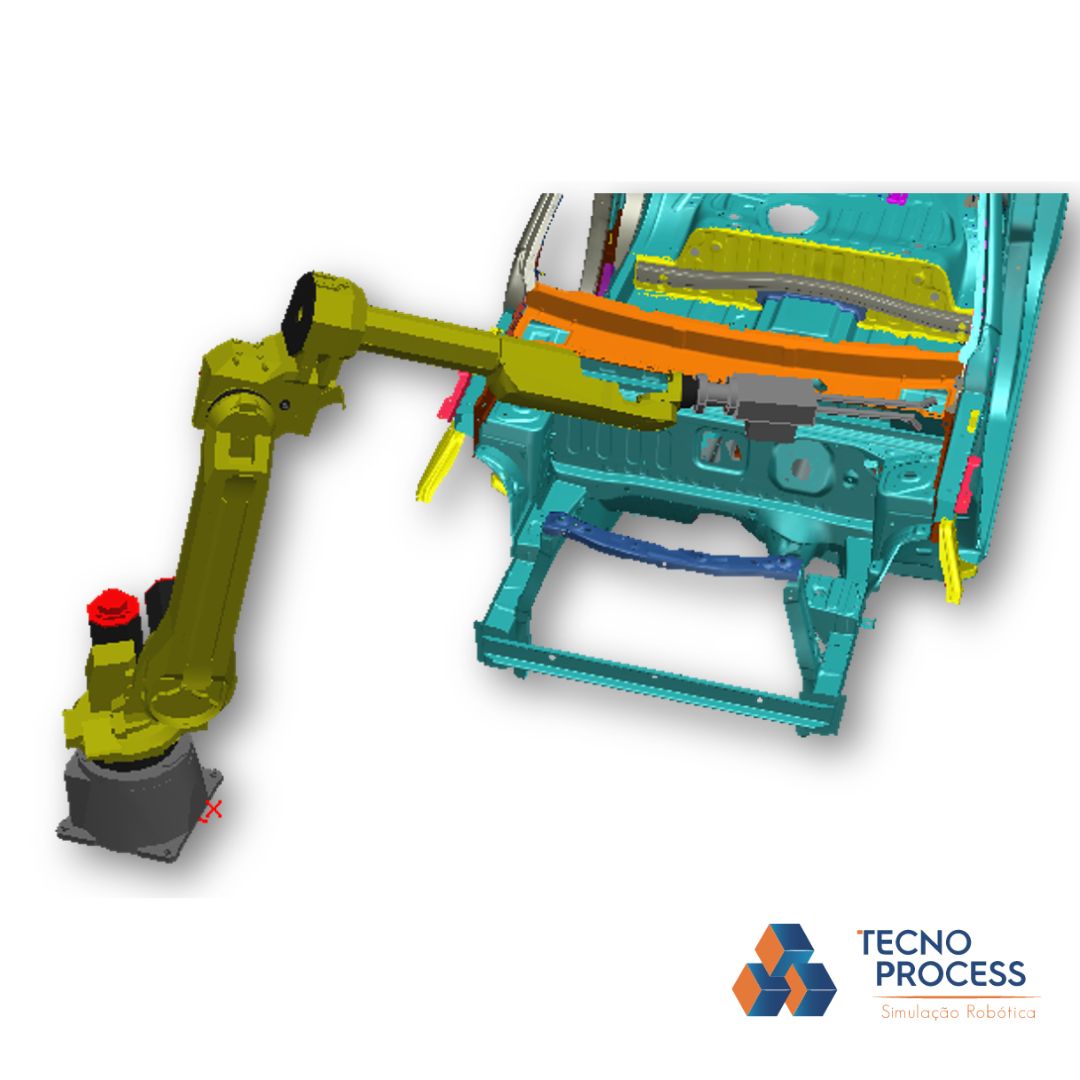

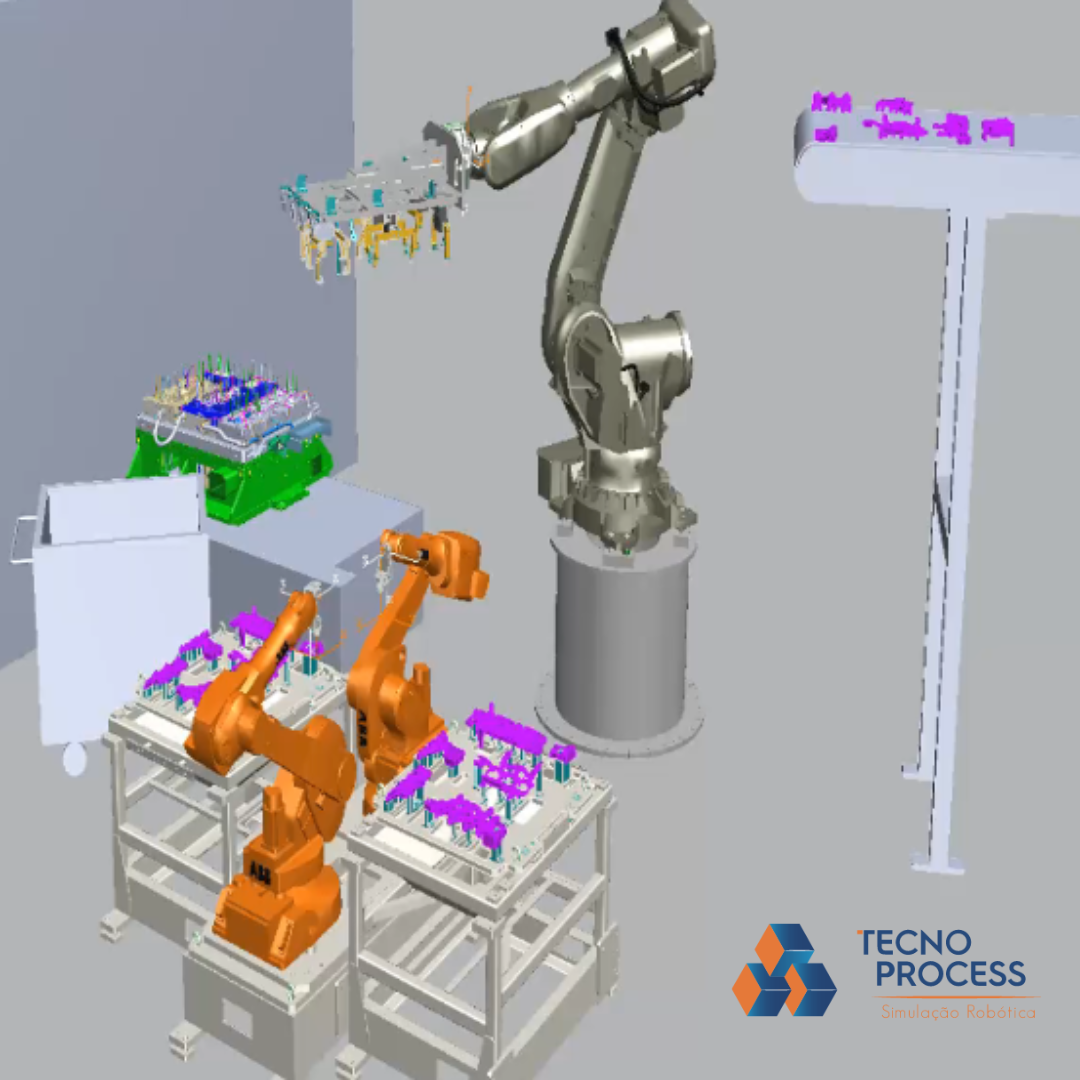

To implement the productivity in the company, it might be easier than you think, and the industry, or a person responsible for use of the software they are unable to predict any specific situation, such as collisions, blind spots, precise positioning of the robot, in addition to the connection between the machines, tools and devices for industrial applications. This makes it easier to change or update has built in the industry.

The service of process simulation the Tecnoprocess done all of this and it still helps those who are involved in the process of your business or the industry don't make the same mistakes of the past through the collection and analysis of detailed data.

Do not leave a review: to view software for the simulation of the process.

Don't look for potential bottlenecks in the company

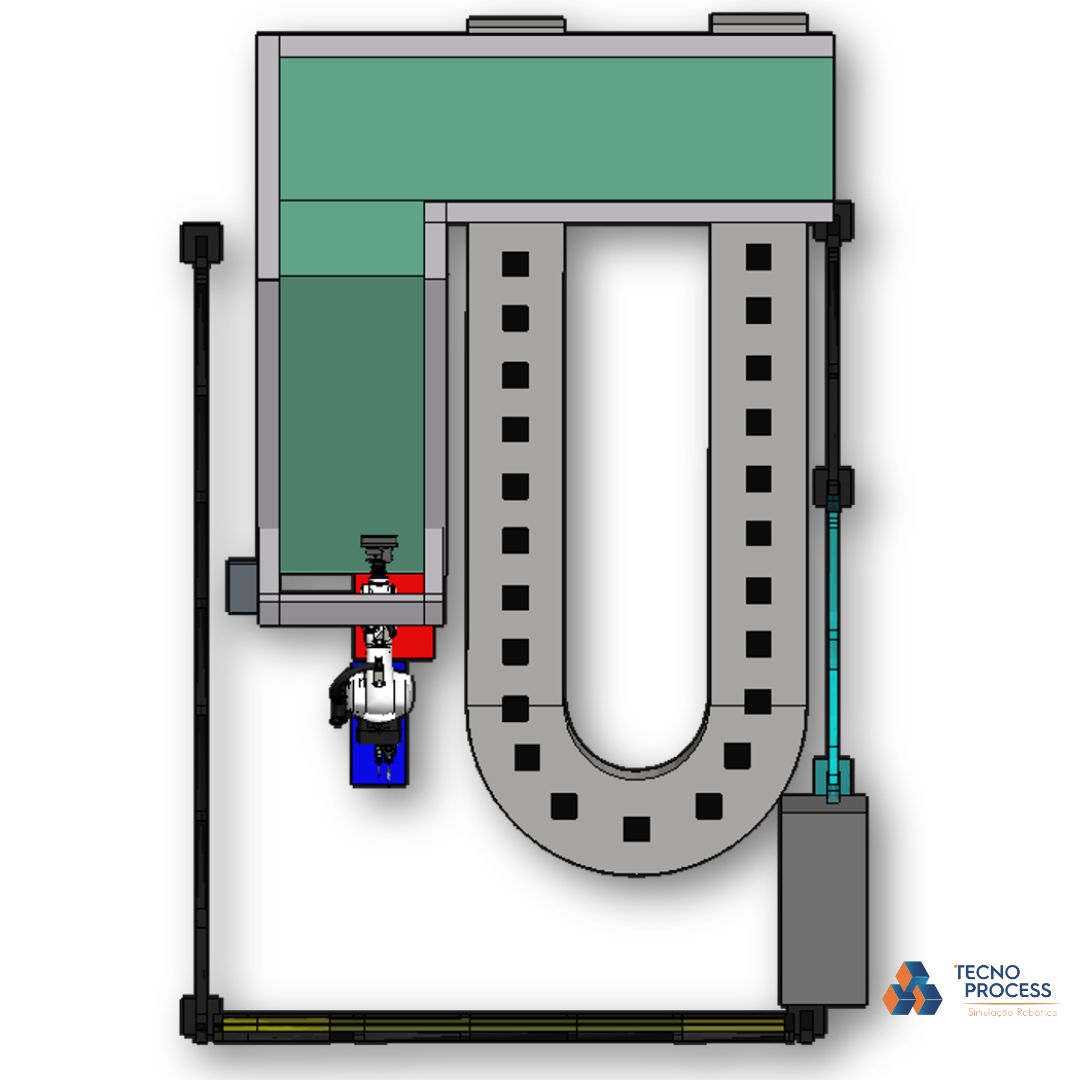

In addition to the fear of change that can bring about a significant improvement to your project, it is necessary first of all to be investigated for the possible positions of bottlenecks. That is, to identify the activities that you fail, or to last longer than necessary, leading to a reduced capacity of the production in relation to the demands of that industry, or a company.

It is worth noting that, after the identification of the bottleneck, it is necessary to make a comprehensive analysis of the current process, in a way that would allow the company to simulate alternative scenarios to a certain sector of that industry.

For this to happen, and the productivity will rise, the industry will need to rely on a software for the simulation of alternative scenarios in conjunction with the simulation of logistics flowsthis is nothing more than you to simulate the flow, transport, and delivery of a product.

Read it now!: I want the software for the simulation of the flow.

Skip to the benefits of industry 4.0

Sometimes, the owners of the industries, even if you ask, " how do to automate a process currently, however, they do not know where to start.

It constitutes the industry 4.0 apply some of the actions in your business, - such as a rnteligência artificial, robotic automation, the internet of things and concepts that will help in the increase of their competitiveness. The benefits are a guarantee of the efficiency and the productivity growth of the manufacturing processes.

Industrial robots can work at it every day, without supervision, in addition to being able to be programmed to make precise movements, and repetitive way that's fast and reliable for the whole production line.

Be sure to check out all the solutions of the Tecnoprocess robot!

Gain access to: industry 4.0

Conclusion

Did you know that it is possible to solve all the problems in the productivity of your business Tecnoprocess?

To tecnoprocess this is a company that specializes in providing cost-effective solutions, and custom, resulting in increased productivity, in economics, and optimization of all steps of the manufacturing processes.

Got questions about the software and bots can be deployed in your industry?

Please click on the link below to talk to our experts!